2024 / 12 / 12

Understanding Nitrous Oxide Cylinders and Suppliers in China

Table of Contents

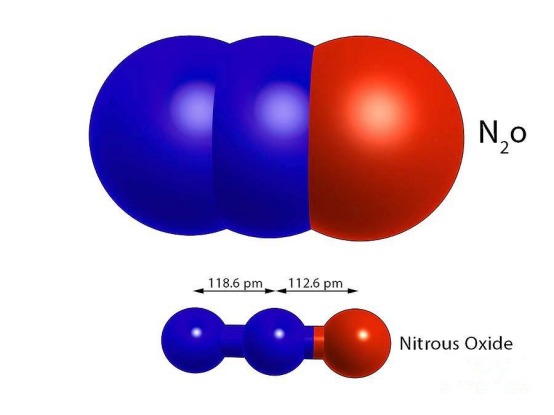

Nitrous oxide (N₂O), often called “laughing gas,” is a versatile compound with widespread applications. From culinary innovations to medical uses and industrial processes, the demand for reliable nitrous oxide cylinders has grown significantly. Among global players, China has emerged as a leading supplier, offering advanced manufacturing, competitive pricing, and stringent quality standards.

This article delves into the diverse applications and essential purity standards of nitrous oxide, emphasizing the role of nitrous oxide cylinders and exploring how China contributes to this dynamic market.

The Role of Nitrous Oxide Cylinders

Nitrous oxide cylinders are specialized containers designed to store and deliver N₂O under high pressure. They come in various sizes and configurations, tailored for different industries. These cylinders are indispensable in maintaining the gas’s stability, ensuring safety, and facilitating efficient use.

Types of Nitrous Oxide Cylinders

- Small-Volume Cylinders: Typically 8g chargers are used in home kitchens for whipped cream dispensers. Portable and convenient for occasional or low-volume use.

- Medium-Size Cylinders: Ranging from 320g to 1364g, ideal for small cafes, restaurants, and catering businesses. Strike a balance between capacity and portability.

- Large Cylinders and ISO Tanks: Industrial-grade options include 2000g cylinders and ISO tanks for large-scale operations. Essential in high-consumption scenarios like manufacturing and healthcare.

Key Applications of Nitrous Oxide

1. Culinary Use

Nitrous oxide plays a pivotal role in the food industry. Its most recognized application is in creating light and fluffy whipped cream, a staple in desserts and beverages. Food-grade nitrous oxide, stored in cylinders, meets strict purity standards (99.9% or higher) to prevent contamination and ensure safety for human consumption.

- Home Kitchens: Small-volume chargers are popular among home cooks for occasional use.

- Professional Kitchens: Larger cylinders, like the 1364g and 2000g sizes, cater to restaurants and large-scale catering businesses.

Beyond whipped cream, nitrous oxide is used in molecular gastronomy to infuse flavors or create foams, adding sophistication to dishes.

2. Medical Applications

In the medical field, nitrous oxide is widely used as an anesthetic and analgesic. Hospitals and dental clinics rely on high-purity (99.995% or higher) medical-grade nitrous oxide. These cylinders are designed to meet rigorous safety and regulatory standards to ensure patient safety and effectiveness.

Applications include:

- Pain management during minor surgical procedures.

- As a sedative in dental practices.

- Emergency relief in ambulances for pain and anxiety.

3. Industrial and Automotive Uses

In the industrial sector, nitrous oxide serves as a critical oxidizer in semiconductor manufacturing and is used to enhance performance in automotive racing. Industrial-grade nitrous oxide cylinders are built to withstand high pressures and meet specific purity levels suited to their application.

Purity Standards of Nitrous Oxide Cylinders in Different Applications

Purity is a fundamental requirement for nitrous oxide cylinders, directly influencing performance, safety, and compliance across applications. Impurities in nitrous oxide can cause operational inefficiencies, compromise product quality, and even pose significant health risks. Therefore, sourcing cylinders from reputable manufacturers with rigorous quality control processes is essential.

1. Food-Grade Nitrous Oxide

- Purity Requirement: Minimum 99.9%.

- Significance: Food-grade nitrous oxide is used in culinary settings, such as whipping cream and creating foams in molecular gastronomy. Even trace contaminants can alter the flavor or safety of food products, potentially making them unfit for consumption.

- Compliance Standards: This grade must meet strict regulations, including FDA standards, ensuring it is safe for ingestion and free from impurities like oils, metals, or other toxic residues.

2. Medical-Grade Nitrous Oxide

- Purity Requirement: Typically 99.995% or higher.

- Significance: In healthcare, nitrous oxide is utilized for anesthesia and pain management. The presence of impurities could lead to adverse reactions or reduce the effectiveness of treatments. For instance, contaminants may trigger respiratory issues or compromise patient safety during surgical procedures.

- Regulatory Oversight: Authorities such as the FDA and CE enforce stringent quality and safety standards to ensure the gas’s consistency, sterility, and purity for medical applications.

3. Industrial-Grade Nitrous Oxide

- Purity Requirement: Varies based on the specific application. Such as the semiconductor manufacturing purity standard is at least 99.999% (often referred to as 5N or higher).

- Significance: Industrial uses, including semiconductor manufacturing and automotive applications, demand high precision and efficiency. Impurities can lead to defective products or performance issues. For example, in automotive racing, contaminants might disrupt the combustion process, and in semiconductor manufacturing, they could affect the production of microchips.

- Special Requirements: Some industries may demand tailored purification levels to meet their unique technical specifications.

China’s Role in the Nitrous Oxide Cylinder Market

China has become a pivotal player in the global nitrous oxide market, offering high-quality cylinders at competitive prices. Manufacturers like Rotass have established themselves as reliable suppliers, catering to diverse industries worldwide.

Advantages of Chinese Manufacturers

- Manufacturing Expertise: Advanced facilities capable of producing cylinders across all sizes and purity levels. Customization options for specific industrial or culinary needs.

- Cost Efficiency: Competitive pricing without compromising quality. Economies of scale enable lower costs for global buyers.

- Global Distribution: Extensive networks ensure fast delivery to international markets. Warehousing in strategic locations like the U.S. and Europe for quicker turnarounds.

- Compliance and Quality Assurance: Adherence to stringent standards, including FDA, CE, and ISO certifications. Comprehensive quality control to ensure consistency and reliability.

Choosing a Supplier: Why Rotass Stands Out

Rotass is a prominent name in the nitrous oxide market, offering an extensive range of cylinders tailored to diverse applications.

- Product Variety: Rotass provides an array of cylinder sizes, from compact 8g chargers to large 2000g units. Their products cater to both individual and industrial users, ensuring versatility.

- Global Reach: With a robust distribution network, Rotass serves clients worldwide, ensuring timely deliveries and comprehensive support. Their ability to customize cylinders based on branding or specific industry needs sets them apart.

- Commitment to Quality: Each Rotass cylinder undergoes rigorous quality control processes to ensure compliance with safety and performance standards. This dedication has earned the brand a reputation for reliability.

In Summary

Nitrous oxide cylinders are essential tools across industries, from enhancing culinary creations to powering medical and industrial processes. Ensuring the right purity levels and selecting the appropriate cylinder size are crucial for safety and efficiency.

China’s role as a leading supplier has revolutionized the nitrous oxide market, offering high-quality, cost-effective solutions. Companies like Rotass exemplify this expertise, providing reliable cylinders that meet diverse needs. Whether you’re a home cook, a medical professional, or an industrial user, choosing a trusted supplier is key to unlocking the full potential of nitrous oxide.