2025 / 03 / 04

The Importance of a Trusted N2O Supplier in Semiconductor Manufacturing

Table of Contents

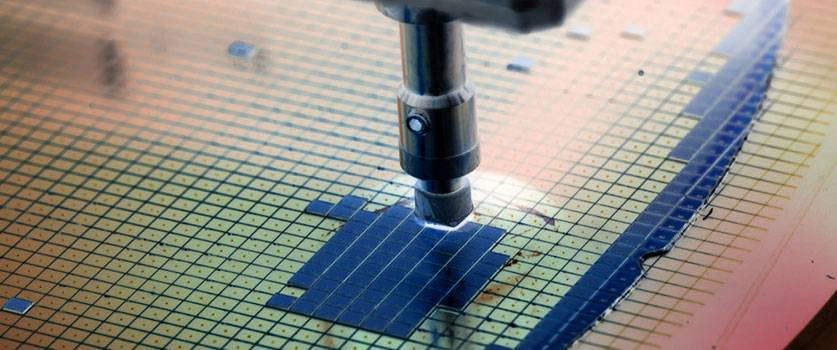

In the rapidly evolving landscape of modern technology, semiconductors stand as the cornerstone of innovation. From smartphones and supercomputers to medical devices and aerospace technology, semiconductor devices permeate every facet of our lives. Behind the intricate circuitry of these tiny chips lies a complex network of processes and chemical reactions. Among the essential gases utilized in this industry, nitrous oxide (N₂O) plays a pivotal role. This article delves into the critical applications of nitrous oxide in semiconductor manufacturing and explores the advantages of partnering with a reliable nitrous oxide supplier like Rotass.

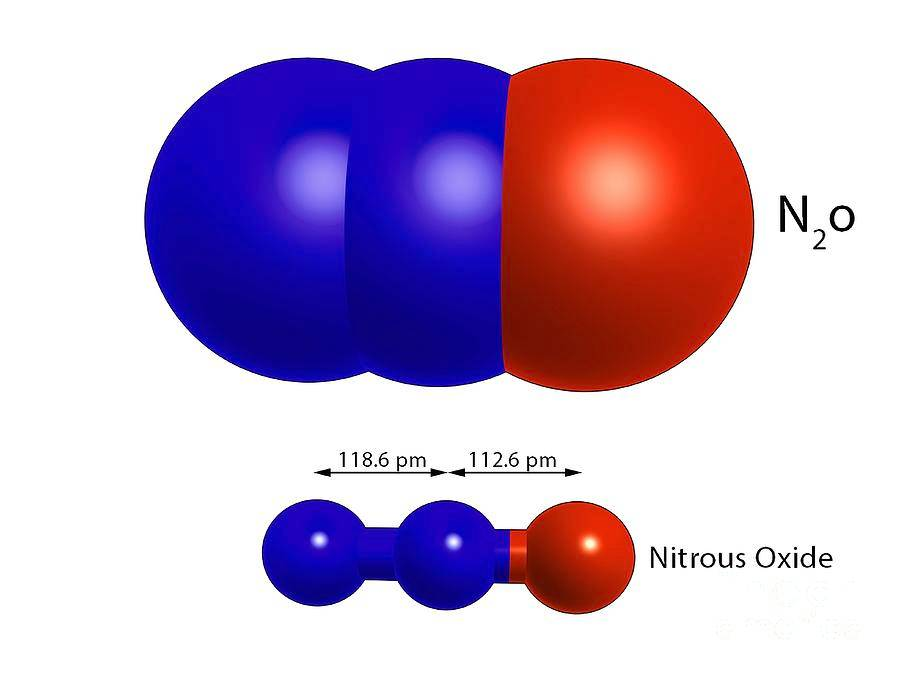

Chemical Properties and Production of Nitrous Oxide

Chemical Equation:

Nitrous oxide is primarily produced through the thermal decomposition of ammonium nitrate (NH₄NO₃), as represented by the following chemical equation:

NH₄NO₃ → N₂O + 2H₂O

This reaction occurs under controlled temperatures, yielding nitrous oxide gas and water vapor.

Production Methods

Industrial production of high-purity nitrous oxide demands rigorous control of reaction conditions and purification processes. High-quality ammonium nitrate is heated to precise temperatures to prevent the formation of byproducts. The resulting gas undergoes multi-stage cooling and filtration to eliminate water vapor and other impurities. Advanced purification techniques, such as molecular sieve adsorption and cryogenic distillation, are employed to achieve the ultra-high purity levels required by the semiconductor industry. A proficient nitrous oxide supplier, such as Rotass, utilizes advanced purification technologies and stringent quality control systems to ensure the delivery of high-purity nitrous oxide that meets semiconductor industry standards.

Applications of Nitrous Oxide in Semiconductor Manufacturing

1. Oxidation and Nitridation

- Thermal Oxidation: At elevated temperatures, nitrous oxide reacts with silicon wafer surfaces to form high-quality silicon dioxide (SiO₂) films. These films serve as crucial insulating and passivation layers in semiconductor devices.

- Plasma Nitridation: Nitrous oxide plasma is used to nitride silicon and other semiconductor materials, creating silicon nitride (Si₃N₄) films. Silicon nitride’s excellent dielectric properties make it essential for memory and logic devices.

- Gate Oxidation: In advanced CMOS processes, nitrous oxide is used to form high-quality gate oxide layers, enhancing device performance and reliability.

2. Chemical Vapor Deposition (CVD)

- Silicon Dioxide Film Deposition: Nitrous oxide reacts with silane (SiH₄) or other silicon source gases in CVD reactors to deposit silicon dioxide films.

- Silicon Nitride Film Deposition: Nitrous oxide reacts with dichlorosilane (SiH₂Cl₂) or ammonia (NH₃) to deposit silicon nitride films.

- Silicon Oxynitride Film Deposition: By carefully controlling reaction conditions, silicon oxynitride (SiON) films with tunable dielectric constants can be deposited.

3. Plasma Processing

- Plasma Cleaning: Nitrous oxide plasma is used to remove organic contaminants and particles from semiconductor surfaces, ensuring cleanliness.

- Plasma Etching: In specific processes, nitrous oxide plasma is employed for etching semiconductor materials.

4. Other Applications

- Balance Gas: Nitrous oxide serves as a balance gas in semiconductor manufacturing, maintaining stable reactor environments.

- Doped Silicon Dioxide Films: It can be used to create doped silicon dioxide films through CVD, modifying their electrical and optical properties.

Cream charger pressure regulators are important for controlling the pressure of gas, typically nitrous oxide (N2O), used to whip cream. By precisely regulating the gas pressure, these regulators ensure the consistent texture and volume of whipped cream, meeting the demands of various culinary and industrial applications.

However, the operation of cream charger pressure regulators may present a learning curve for some users. This raises questions about the complexity of their operation, the extent of training required, and the ease with which operators can become proficient in using these devices. In this article, we will delve into these aspects to provide a comprehensive understanding of the operational demands associated with cream charger pressure regulators.

Nitrous OxidePurity Requirements in Semiconductor Manufacturing

Semiconductor manufacturing demands extremely high gas purity. Even trace impurities can degrade device performance or lead to device failure. Therefore, the industry typically requires nitrous oxide with a purity of 99.999% (5N) or higher.

- Impurity Control: Strict limits are placed on impurities such as moisture, oxygen, carbon dioxide, and nitrogen oxides, often requiring levels in the parts per billion (ppb) range.

- Particle Control: Rigorous control of particles in the gas is essential to prevent wafer surface contamination.

- Analytical Testing: High-precision gas analysis instruments, such as mass spectrometers and laser spectrometers, are used for real-time monitoring of gas purity.

Advantages and Considerations of Nitrous Oxide in Semiconductor Manufacturing

Advantages

- Nitrous oxide offers better control over oxidation and nitridation processes compared to oxygen, resulting in uniform and dense films.

- It is relatively stable at high temperatures, allowing for precise control of reaction rates.

- High-purity nitrous oxide minimizes impurity introduction, enhancing device yield.

Considerations

- Nitrous oxide is a greenhouse gas, necessitating proper abatement.

- High-temperature decomposition can produce nitrogen oxides (NOx), requiring exhaust gas treatment.

- Leaks can pose occupational safety hazards, demanding strict safety protocols.

Advantages of Choosing Rotass as Your Nitrous Oxide Supplier

1. Gas Purity and Quality Control:

Rotass employs advanced purification technologies and rigorous quality control to ensure ultra-high purity nitrous oxide. Precise analytical testing confirms that impurity levels meet stringent semiconductor process requirements.

2. Stable Supply and Reliability:

Semiconductor production relies on a continuous gas supply. Rotass offers a robust supply chain and logistics, ensuring timely and reliable delivery. High-quality nitrous oxide tanks and manufacturing processes guarantee safe and reliable gas storage and delivery.

3. Technical Support and Professional Service:

Rotass provides expert technical support, assisting customers in optimizing gas usage and resolving process challenges. They also offer customized gas solutions to meet specific customer needs.

4. Safety:

Rotass adheres to strict safety management practices, ensuring compliance with relevant standards. Using a reliable Nitrous Oxide tank from a reputable Nitrous Oxide supplier is very important.

5. Cost-Effectiveness:

Rotass offers competitive pricing without compromising gas quality or supply reliability, helping customers reduce production costs.

Conclusion

Nitrous oxide is indispensable in semiconductor manufacturing, offering high purity and controllability for critical processes. Rotass, as a reliable nitrous oxide supplier, provides advanced technology, stringent quality control, and professional service, earning customer trust. As semiconductor technology advances, the applications of nitrous oxide will continue to expand.