2024 / 08 / 12

Something About Food-Grade Nitrous Oxide Cylinder Leaks

Food-grade nitrous oxide is a widely used gas in various industries, including food processing. While essential for many applications, it also presents potential hazards if not handled and stored correctly. One of the primary concerns is the risk of cylinder leaks, which can lead to a range of safety and health issues. This article will delve into the critical aspects of food-grade nitrous oxide cylinder safety, covering steps to detect leaks, potential health risks associated with leaks, and emergency procedures to follow in case of a leak. By understanding these key areas, individuals and businesses can significantly reduce the risks associated with handling and storing nitrous oxide cylinders.

Steps to Detect Leaks in Food-Grade Nitrous Oxide Cylinders

Food-grade nitrous oxide is a commonly used gas in various industries, including food processing. Ensuring the integrity of the cylinders containing this gas is crucial for safety and product quality. Here are several methods to detect leaks in food-grade nitrous oxide cylinders:

1. Sensory Inspection

- Auditory: Listen for a hissing sound, which is a classic indicator of a gas leak.

- Olfactory: While nitrous oxide is odorless, a strong or unusual smell might suggest contamination or a leak of another substance.

2. Soap Bubble Test

- Application: Apply a soapy solution to the cylinder’s valve, connections, and any suspected leak points.

- Interpretation: The formation of bubbles indicates a gas leak at that specific location.

3. Balloon Test

- Procedure: Attach a flexible tube to the cylinder’s outlet and then connect a balloon to the other end of the tube.

- Indication: If the balloon inflates without opening the cylinder valve, there’s a leak.

4. Chemical Reaction Test

- Specificity: This method is suitable for detecting certain toxic gases and might require specialized equipment and chemicals.

- Observation: The reaction between a specific chemical reagent and the leaking gas often produces a visual change.

Safety Precautions

When conducting leak detection, it’s essential to prioritize safety:

- Ventilation: Ensure adequate ventilation to disperse any leaked gas.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as gloves and safety glasses.

- Emergency Procedures: Have emergency procedures in place and know how to respond to a gas leak.

- Professional Assistance: If you’re unsure about any step or encounter a significant leak, contact a qualified technician or the gas supplier immediately.

Health Risks Associated with Leaks from Food-Grade Nitrous Oxide Cylinders

While the nitrogen and carbon dioxide in food-grade nitrous oxide cylinders are generally considered harmless to humans due to their presence in the natural environment, a leak can pose significant health risks.

- Oxygen Depletion: In confined spaces, leaks can rapidly dilute the oxygen concentration, leading to hypoxia (oxygen deficiency) and potentially suffocation.

- Frostbite Risk: Liquid carbon dioxide is extremely cold. A leak can cause frostbite, especially if it comes into direct contact with skin or mucous membranes.

- Asphyxiation: A rapid increase in carbon dioxide concentration can lead to asphyxia, especially in enclosed spaces.

- Decompression Sickness: Individuals who have been exposed to high-pressure environments, such as divers, may be at risk of decompression sickness if they are exposed to a rapid decrease in pressure. Nitrogen bubbles can form in the body, causing pain, joint problems, and in severe cases, paralysis or death.

- Contaminant Risk: If the food-grade nitrous oxide is not pure, it may contain contaminants such as other gases or particulates. These contaminants can be transferred to food products and pose a health risk.

Specific to Food-Grade Nitrous Oxide

- Food Contamination: Leaks can contaminate food products with the gas or any contaminants present in the gas. This can alter the taste, texture, or nutritional value of food and may introduce harmful substances.

- Equipment Damage: Prolonged exposure to leaking nitrous oxide can damage equipment and facilities, increasing the risk of accidents and injuries.

Safety Precautions

- Ventilation: Ensure adequate ventilation in areas where nitrous oxide cylinders are stored or used.

- Emergency Procedures: Develop and implement emergency procedures for handling gas leaks, including evacuation and first aid.

- Personal Protective Equipment: Use appropriate PPE, such as gloves, safety glasses, and respiratory protection, when handling cylinders or responding to a leak.

- Regular Inspections: Conduct regular inspections of cylinders and equipment to identify and address potential issues before they become a hazard.

- Training: Provide training to all personnel involved in the handling and storage of nitrous oxide cylinders.

While food-grade nitrous oxide is generally safe when used correctly, leaks can pose serious health hazards. By understanding these risks and implementing appropriate safety measures, you can minimize the likelihood of accidents and protect the health of workers and consumers.

Emergency Procedures for Food-Grade Nitrous Oxide Cylinder Leaks

- Immediate Evacuation: Upon detecting a leak in a food-grade nitrous oxide cylinder, promptly evacuate the area. Ensure all personnel move to an upwind or well-ventilated location, and establish a perimeter around the leak site to restrict access.

- Valve Closure: If the leak is minor, attempt to close the cylinder valve to halt the gas release.

- Power Isolation: Cut off all power sources within the affected area to prevent electrical sparks or short circuits that could ignite the gas.

- Ventilation: Open windows and doors, and use fans or other ventilation equipment to accelerate the dispersion of the gas and reduce its concentration.

- Notify Experts: Immediately contact the gas supplier, emergency response team, or a qualified technician. Provide them with detailed information about the leak, including its location, severity, and any actions taken.

- Personal Protective Equipment (PPE): All personnel involved in the incident should wear appropriate PPE, such as self-contained breathing apparatus (SCBA) and cold-insulating clothing, to protect against inhalation of the gas and exposure to cold temperatures.

- Prevent Secondary Incidents: Until the arrival of experts, avoid any actions that could trigger secondary incidents, such as operating electrical equipment or using open flames in the contaminated area.

- Documentation and Investigation: After the incident, document all relevant details and conduct a thorough investigation to determine the cause of the leak and prevent future occurrences.

Additional Considerations

Emergency Response Plan: Every facility that handles food-grade nitrous oxide should have a detailed emergency response plan outlining the specific steps to be taken in case of a leak.

- Training: All personnel should be trained in emergency procedures, including the use of PPE and communication protocols.

- Regular Inspections: Conduct regular inspections of cylinders and equipment to identify and address potential issues before they lead to a leak.

- Spill Kits: Have appropriate spill kits available to contain and neutralize any leaked gas.

- Emergency Contacts: Maintain a list of emergency contacts, including local fire departments, medical facilities, and the gas supplier.

By following these guidelines and being prepared for emergencies, you can minimize the risks associated with food-grade nitrous oxide leaks and protect the safety of personnel and the environment.

Conclusion

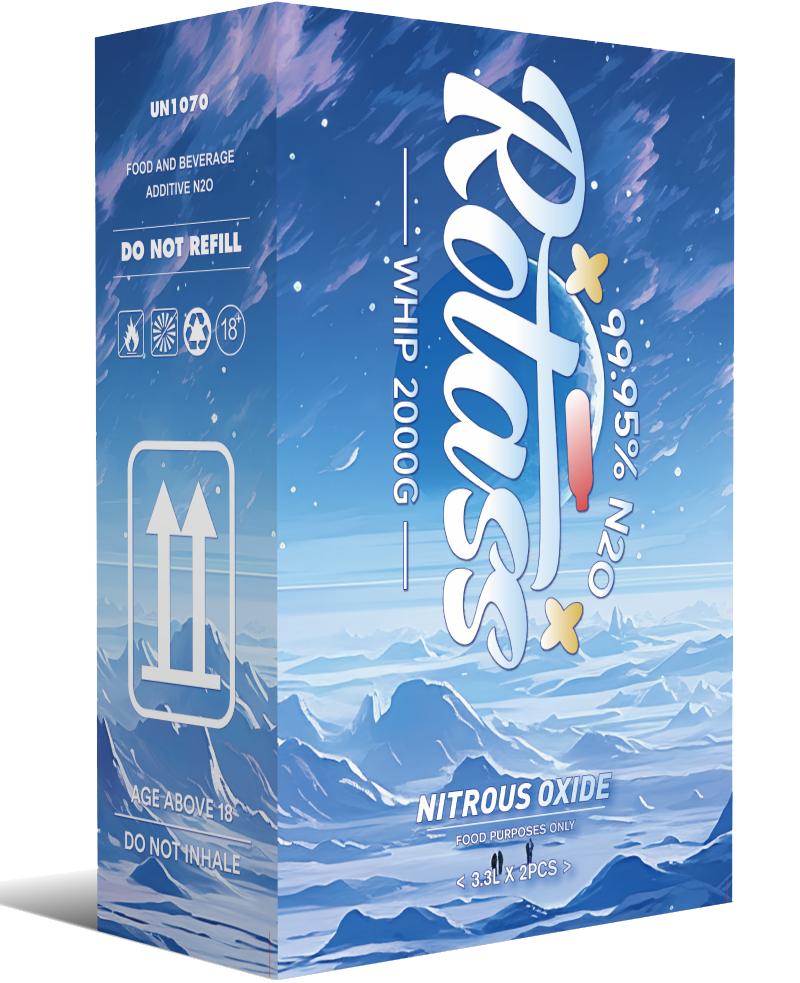

The safe handling and storage of food-grade nitrous oxide cylinders are paramount to protecting human health, property, and the environment. By implementing the steps outlined in this article for leak detection, understanding the associated health risks, and establishing comprehensive emergency procedures, individuals and organizations can significantly mitigate the dangers posed by nitrous oxide cylinder leaks. Regular inspections, employee training, and adherence to safety guidelines are essential for preventing accidents and ensuring the well-being of all personnel. Please follow Rotass to make early detection and proper response is crucial in minimizing the impact of a nitrous oxide leak.